Behind every factory, refinery, or plant for processing, there’s a machine quietly doing the heavy lifting moving fluids day in and throughout the day without pause. Industrial pumps aren’t seen until there is an issue, but they are crucial for modern-day industry. The different between a smoothly running operation and a costly downtime is often determined by the selection of the screw pump and parts manufacturer, or Industrial Centrifugal Pump Manufacturers.

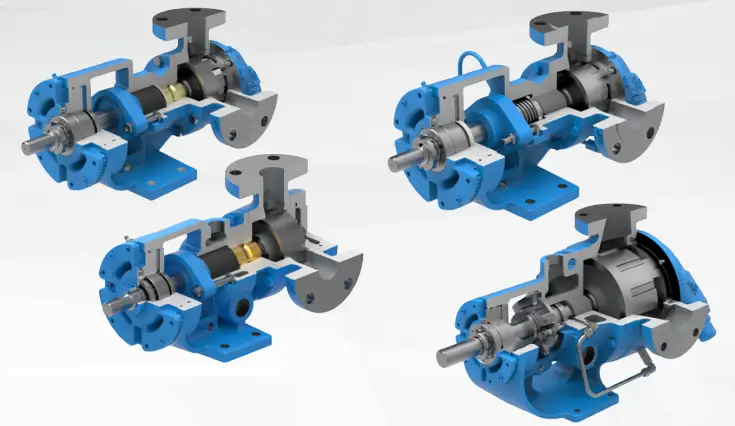

Image credit: lepuseal.com

These pumps are built for environments in which the reliability of the pump is essential. These pumps are designed to transfer fluids like oils, water, chemicals and even chemicals through intricate systems. In contrast to smaller commercial pumps industrial pumps are engineered to last for a long time, using harsh substances, and demanding conditions that leave no room to take shortcuts.

Understanding Centrifugal Pumps and Screw Pump Applications

Centrifugal pumps have been used in industrial applications for several years. Their basic design, constant flow, and energy efficiency are a good choice for the transportation of large volumes of medium to low viscosity fluids. This is why many industrial centrifugal pump manufacturers focus heavily on refining impeller geometry, casing materials, and motor performance. These improvements can reduce energy consumption while maintaining consistent output across long operating cycles.

Screw pumps perform a totally different but equally vital function. Screw pumps are perfect to be used in applications that need consistency of fluid like harder and thicker materials. Sludges, oils, and viscous chemicals require a smooth, non-pulse movements, which screw pumps deliver with precision. A manufacturer of screw pumps and pump components that is an expert in this field is aware of the effect internal tolerances, rotor design and seal design can have on performance and life under pressure.

The pumps are made to meet a variety of industrial requirements, from simple water transfer to the handling of chemicals and processes.

Why Pump Parts Matter More Than Many Expect

The components of a pump are only as reliable and durable as they can be. The mechanical seals, shafts and bearings that comprise the pump are always exposed to friction, pressure and wear. Even small component failures over time can result in vibrations, leaks or system shut downs. It is vital to have access to quality spare parts, as well as pumps.

Instead of purchasing parts from various suppliers, many industrialists prefer dealing with companies that offer full pump solutions. The availability and quality of compatible components reduces downtime for equipment and prolongs its life. This makes maintenance easier and assures that equipment functions within its specifications.

This approach is exactly why Lepu Seal, your one-stop source for pumps and pump parts, is now an option for reliable industrial buyers. Lepu Seal offers both complete pumping systems and an extensive assortment of replacement parts for long-term stability in various industries.

For Industries That Can’t afford downtime

In chemical plants and refineries and in the manufacturing industry, wastewater treatment and energy production, industrial pumps are commonly employed. In these kinds of settings, malfunctions are not only annoying but they could also disrupt entire production processes. Testing procedures, manufacturing standards and quality control are essential.

Before shipping, trustworthy manufacturers ensure that their pumps are tested under actual operating conditions. Each unit is tested to determine the performance, pressure, and materials. This focus on detail makes it possible for users to feel secure in their equipment, knowing that it is built to last.

As businesses continue to expand and evolve, the need for reliable pumps and durable components keeps growing. Utilizing experienced Industrial Centrifugal Pump manufacturers and trusted suppliers of pumps ensures systems remain efficient, resilient and up for the demands of continuous operation. In the final analysis, reliability isn’t only an option, it’s the underlying principle of the success of any industrial enterprise.